Inventory Optimization is a Process

Inventory investments are often considered a necessary evil required to satisfy customer service requirements in order to capture maximum revenue. When managed correctly, however, inventory can become a key strategic asset to drive profitable revenue growth and competitive advantage. The challenge is in establishing a sustainable foundation for effective inventory management that rapidly adapts to the constant changes in business dynamics and promotes prioritized continuous improvement.

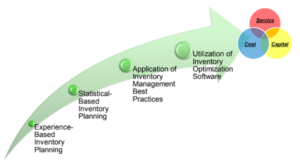

Many companies pursue a “silver bullet” solution by implementing sophisticated inventory optimization software tools but sometimes find that they do not have adequate data accuracy, user skills, process compliance mechanisms or alignment of goals required by the systems to achieve—let alone sustain—desired results. Experience has shown that an 80% perfect solution that is 100% implemented yields better results than a 100% perfect solution that is only 80% implemented. Therefore, a methodical, evolutionary approach to inventory optimization is recommended.

Balancing Service, Cost, and Capital is the Key

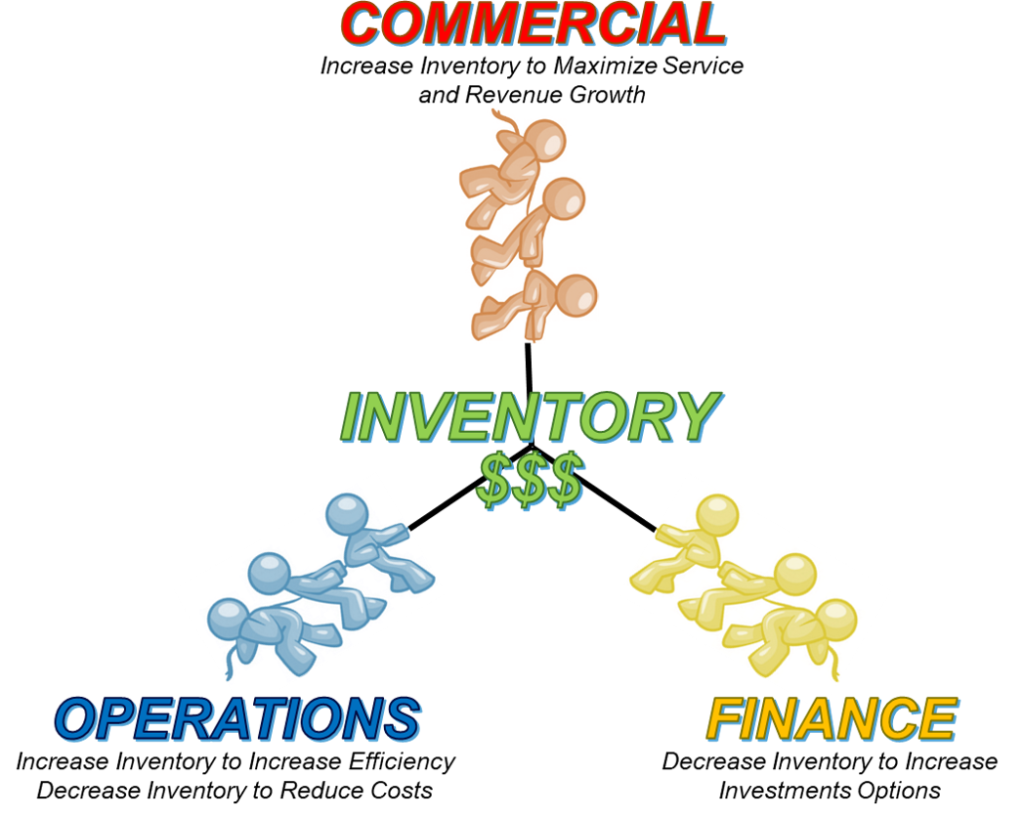

Inventory management priorities typically vary across departments within an organization based on functional performance metrics. Commercial teams tend to focus on service as a driver for revenue growth and prefer to see an abundance of inventory close to the customer. Finance teams tend to focus on working capital as a lever to fund business investments and prefer to see inventory kept to a minimum. Operations teams tend to be held accountable for costs and seek to manage inventory efficiently—perhaps buying inventory in large quantities to maximize economies of scale or reducing inventory to minimize warehousing costs.

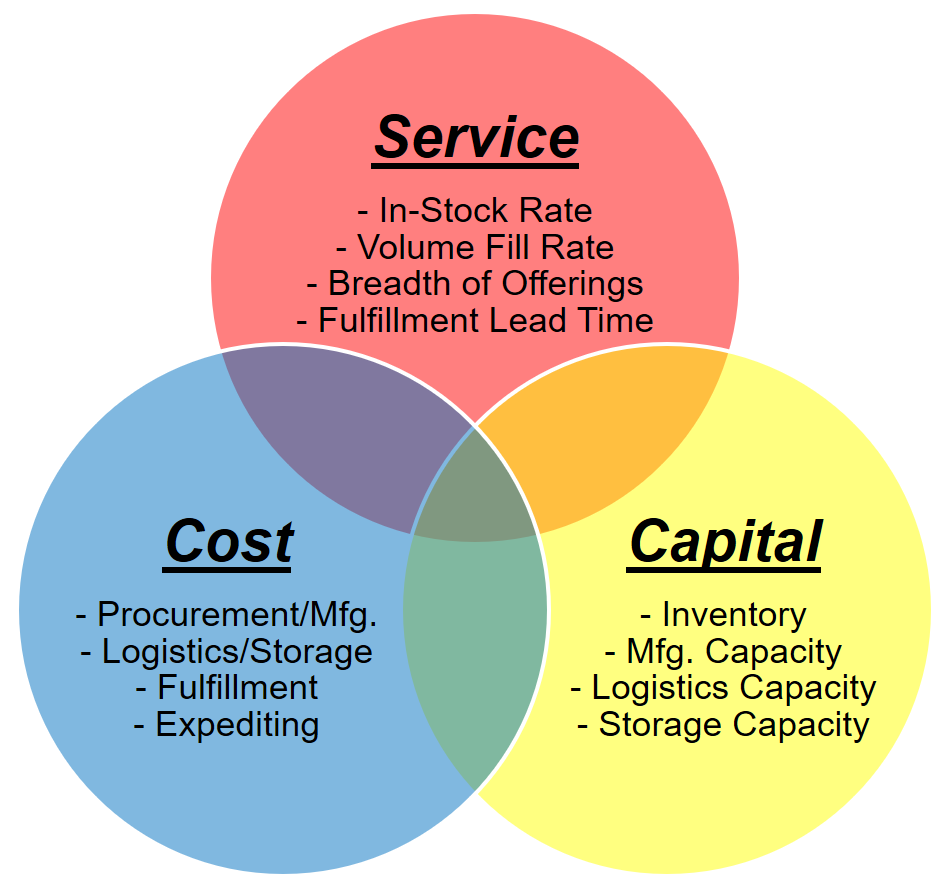

Often, the priorities of a business will change based on recent business performance or a change in leadership and philosophy. The challenge—and the key to success—in navigating these differing priorities is to establish a sustainable balance between service, cost, and capital.

Often, the priorities of a business will change based on recent business performance or a change in leadership and philosophy. The challenge—and the key to success—in navigating these differing priorities is to establish a sustainable balance between service, cost, and capital.

Any one dimension can be improved in a relatively short timeframe, but this is often a recipe for disastrous results (e.g., dramatically reducing inventory levels ultimately erodes customer service and sales, while increasing replenishment and fulfillment expediting costs). Balancing two dimensions can be achieved with focused attention on fundamental principles, but it does not yield sustainable results (e.g., stocking every item in every location can increase customer service and decrease delivery costs by being closer to the customer, but requires higher inventory investments).

A different mindset and approach are required to balance all three dimensions. Consider the analogy of a three-legged stool, where the goal is to keep the seat level through balancing service, cost, and capital.

Start Simple, and Keep It Logical

Start Simple, and Keep It Logical

Too often, companies try to take a giant leap toward a best practice solution (process or software application) that has recently captured the headlines. While these are often technically correct and may be successfully implemented at other companies, they are of little use if the organization does not embrace the outputs or recommendations generated by the solution. If users cannot connect the dots between causes and effects, they do not trust the results produced by these “black box” solutions. Additionally, they may not have the foundational understanding necessary to identify and implement continuous improvements. As a result, these investments in new solutions are often lost as people revert to legacy processes that they understand.

Just like with best practice solutions, it is critical to plan and manage inventory based on data-driven analytics and decision support tools. However, each company’s unique characteristics must be taken into account in order for implementation to be successful. The most effective approach is to leverage simple mathematical calculations and simulation tools that enable interactive what-if analysis and cause-and-effect learning by the user. Increased complexity is only added to the solution as the organization “demands” added capability based on challenges or shortcomings identified through experience. In doing so, the organization is then able to better understand the rationale behind the inventory targets and the unique characteristics of their business that have the greatest impact on inventory productivity.

Our Evolutionary Approach

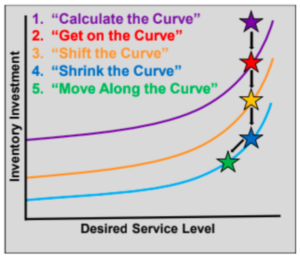

Returning to the stool analogy, the first task is to “level the seat,” then work to “shorten the legs”—do more with less—while maintaining balance. This concept is applied using a calculated statistical curve familiar to inventory management practitioners, which illustrates the exponential inventory investment associated with higher service level goals. The approach begins with an understanding of current inventory performance (service and capital) against the statistical curve. This defines the immediate improvement opportunity available through the adoption of fundamental inventory management principles. Using this baseline as a point of reference, improvement opportunities are then evaluated and prioritized for continuous improvement. Our proven five-step approach:

- Calculate the Baseline Curve — Using a commonly-accepted equation, inventory targets for each item-location combination are calculated based on current attributes of demand and supply that best align with business characteristics. Estimates can be used as a substitute for unknown information and later evaluated to assess precision requirements. This baseline establishes a target for the business based on current performance capabilities.

- Get on the Curve — By comparing historical performance (service and average inventory investment) to the baseline, near-term improvement opportunities to reduce inventory investment, increase service, or realize a combination of both can be quantified. Inventory management processes and control metrics are modified to “right-size” inventory investments in alignment with calculated targets. It is not uncommon to require increased investments for selected items, which is indicative of historical excessive costs in fulfilling demand.

- Shift the Curve — Perform what-if sensitivity analyses by evaluating the effects of changing demand and supply attributes. For example, what if lead time were reduced by one week? What if supply reliability increased by 10%? What if inventory was replenished twice as often? What if forecast accuracy improved by 5%? These results help identify key leverage points to improve inventory productivity and quantify potential benefits.

- Shrink the Curve — A logical but difficult task is to reduce the number of items sold and the number of stocking locations, but the benefits can be significant. Items that do not justify their corresponding inventory investments can be rationalized by evaluating their return on investment. Additionally, the implications of consolidating inventory into fewer stocking locations can be evaluated.

- Move Along the Curve — Not all items are of equal strategic value to a company and, therefore, could have differentiated service level goals. Evaluate (challenge) current service level goals by segmenting products and differentiating objectives for prioritized customers. Each item has a point at which the cost to achieve a high service level exceeds the benefit realized by capturing the incremental sale. Determining this point is critical to move along the curve.

Evolution Before Revolution

Evolution Before Revolution

It’s easy to realize the importance of optimizing inventory investments in support of achieving overall company goals. The challenge is in determining how to achieve and sustain results — the balance of service, cost, and capital. The magnitude of benefits tends to be directly proportional to the adoption of and organizational alignment around a practical approach, and the passion for continuous improvement that is enabled by a solid understanding of foundational concepts. This is achieved by keeping the solution simple, understandable, and agile while being anchored in an analytical understanding of the cause-and-effect relationships and the key drivers of inventory productivity. Allowing the organization to “pull” the evolution of solution complexity fosters knowledge growth.

At some point, a company is ready to transition from practical tactics to more advanced solutions enabled by powerful inventory optimization software. However, by first mastering practical tactics, an organization has a much better understanding of the unique inventory productivity drivers of its business and can better define the solution capability requirements of a future enabling system. Remember: Evolution before revolution.

At some point, a company is ready to transition from practical tactics to more advanced solutions enabled by powerful inventory optimization software. However, by first mastering practical tactics, an organization has a much better understanding of the unique inventory productivity drivers of its business and can better define the solution capability requirements of a future enabling system. Remember: Evolution before revolution.

About River Rock Advisors

River Rock Advisors is a leading value chain management advisory firm that partners with manufacturing and distribution organizations worldwide to develop and implement solutions with a specific focus on cross-functional whitespace challenges. Its analytical approach considers industry- and process-specific metrics to help client leadership teams make data-driven decisions and navigate change effectively.